Inks and Pigments Analysis

Inks and pigments represent complex colloidal systems composed of finely dispersed solid particles suspended in liquid media. These formulations are widely used across printing, coatings, packaging, textiles, electronics, and advanced manufacturing industries. The performance of inks and pigments depends heavily on particle size, dispersion quality, and stability under processing and application conditions. Modern ink systems often contain nanoparticles to enhance color intensity, opacity, conductivity, UV resistance, or functional performance. As formulations become more advanced, precise ink nanoparticle characterization is essential to ensure consistent quality and optimal application results.

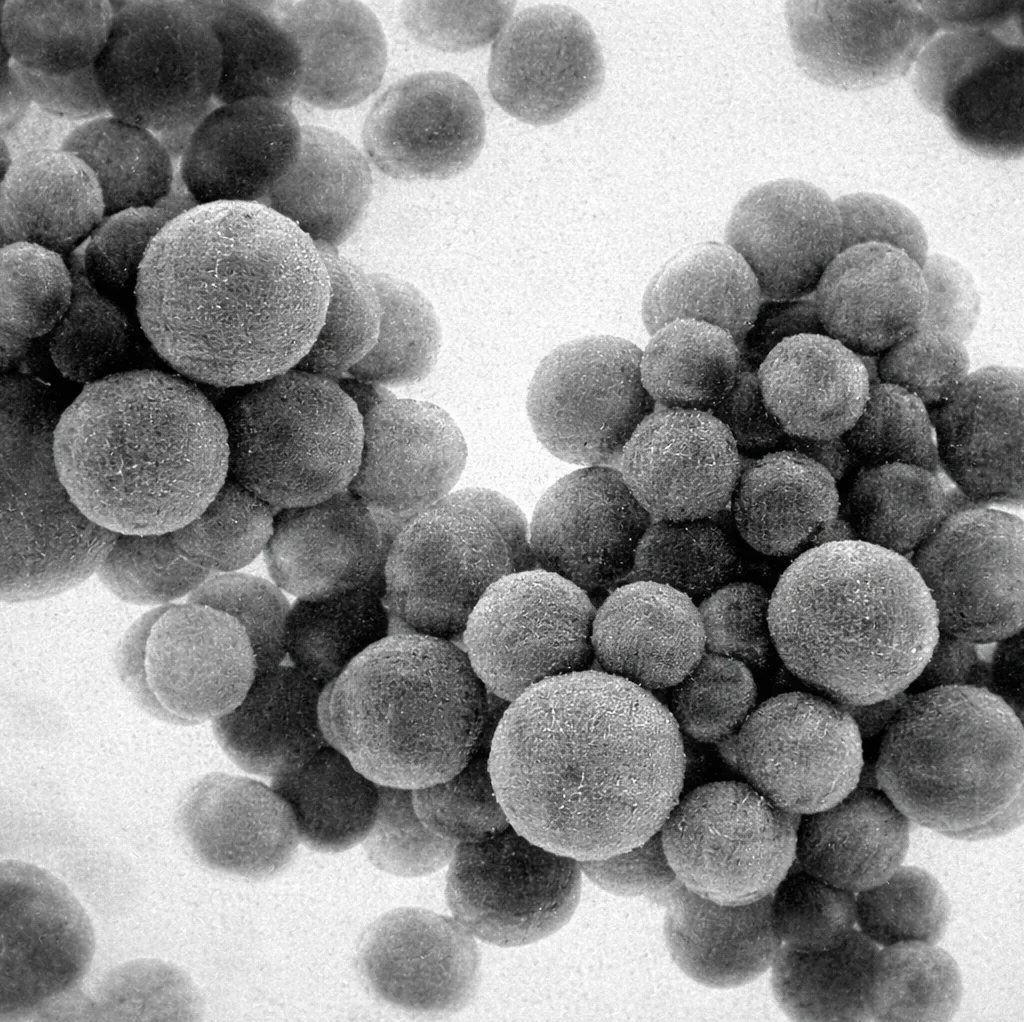

Particle size distribution and dispersion stability directly influence color strength, gloss, print resolution, flow behavior, and drying characteristics. Even minor variations in particle populations can result in sedimentation, nozzle clogging, uneven coating, or reduced product performance. For this reason, pigment aggregation analysis plays a critical role in formulation development and quality control.

NTA for pigments and inks provides particle-level insights into size distribution, concentration, and aggregation behavior in liquid suspensions, supporting improved formulation control and manufacturing consistency.

Fundamentals of Ink and Pigment Systems

Inks and pigments typically consist of:

- Solid pigment particles (organic or inorganic)

- Dispersing agents and stabilizers

- Solvents or aqueous carriers

- Binders and functional additives

Pigment particles may range from tens of nanometers to several hundred nanometers, depending on application requirements. High-performance ink systems such as inkjet, conductive inks, and specialty coatings rely on tightly controlled nanoparticle dispersions.

Common pigment types include:

- Carbon black

- Titanium dioxide

- Organic color pigments

- Metallic nanoparticles

- Functional conductive or magnetic particles

The final performance of these systems is strongly influenced by:

- Particle size and size distribution

- Surface chemistry and charge

- Dispersion stability

- Interparticle interactions

- Processing conditions

These factors make accurate ink nanoparticle characterization essential throughout product development and manufacturing.

Importance of Ink Nanoparticle Characterization

Ink and pigment systems are particularly sensitive to particle size and aggregation behavior. Poor dispersion or uncontrolled aggregation can lead to:

- Reduced color intensity

- Inconsistent gloss or opacity

- Printhead clogging in inkjet systems

- Sedimentation during storage

- Poor coating uniformity

- Reduced electrical conductivity in functional inks

Effective pigment aggregation analysis allows manufacturers to detect early-stage instability and optimize dispersant systems to maintain long-term stability.

Key drivers for accurate analysis include:

- Ensuring batch-to-batch consistency

- Optimizing milling and dispersion processes

- Monitoring storage stability

- Supporting scale-up and process validation

- Meeting strict quality specifications

Traditional ensemble measurement techniques may not fully capture heterogeneous or multimodal particle populations present in complex ink formulations.

NTA for Pigments and Inks

Nanoparticle Tracking Analysis is a single-particle measurement technique that tracks the Brownian motion of individual particles in liquid suspension. When pigment particles or ink nanoparticles are illuminated by a laser beam, scattered light from each particle is recorded by a sensitive camera.

By analyzing particle trajectories, diffusion coefficients are calculated, enabling determination of hydrodynamic diameter and particle concentration.

NTA for pigments and inks enables direct visualization and measurement of dispersed particles and aggregates in their native liquid environment, providing realistic insight into formulation behavior.

Advantages of NTA for Ink Nanoparticle Characterization

- Particle-resolved measurement: NTA measures individual pigment particles and aggregates, allowing detailed pigment aggregation analysis.

- Number-based size distributions: Number-weighted data reveal true particle population characteristics, especially in polydisperse systems.

- Absolute particle concentration measurement: Supports quality assurance and consistency across production batches.

- Aggregation monitoring: Enables detection of agglomerates formed during processing or storage.

- Liquid-state analysis: Measurements are performed directly in dispersion, avoiding artifacts associated with drying or immobilization.

Ink and Pigment Measurement Workflow Using NTA

Ink nanoparticle characterization using NTA typically follows a structured workflow:

- Controlled dilution of the ink or pigment dispersion to an optimal concentration range

- Introduction into a temperature-controlled measurement chamber

- Laser illumination and visualization of individual particles

- Tracking of Brownian motion and trajectory analysis

- Data extraction for size distribution and concentration metrics

This workflow supports reproducible and standardized analysis across research and industrial environments.

Key Parameters in Pigment Aggregation Analysis

- Hydrodynamic Size: Reflects particle behavior in liquid media, including dispersant and binder effects.

- Size Distribution: Number-based distributions reveal multimodal populations and aggregation states.

- Particle Concentration: Supports process monitoring and formulation consistency.

- Aggregation and Stability Behavior: Time-dependent measurements identify early-stage flocculation or instability.

Comparison with Other Ink Nanoparticle Characterization Techniques

- Dynamic Light Scattering (DLS): Provides rapid ensemble measurements but may be biased toward larger aggregates in polydisperse pigment systems.

- Electron Microscopy: Offers detailed structural imaging but requires drying and sample preparation that may alter dispersion characteristics.

- Complementary Role of NTA: NTA for pigments and inks bridges these techniques by combining particle-level resolution with liquid-state analysis, making it particularly valuable for real-world formulation evaluation.

Role of NTA in Ink and Pigment Research and Development

- Formulation optimization: Supports selection of dispersants and milling conditions to minimize aggregation.

- Process control: Monitors particle populations during scale-up and manufacturing.

- Stability studies: Tracks long-term storage behavior and sedimentation risk.

- Functional ink development: Ensures controlled particle size for conductive, magnetic, or specialty inks.

Quality Control and Manufacturing Applications

In industrial production environments, consistent ink nanoparticle characterization is critical for maintaining product quality. NTA supports:

- Batch release testing

- Specification compliance

- Routine pigment aggregation analysis

- Troubleshooting production variability

- Continuous process improvement

Direct measurement of particle size distribution and concentration enhances confidence in printing performance, coating uniformity, and functional ink reliability.

Advanced NTA Capabilities for Pigments and Inks

Modern NTA platforms integrate improved optics, automated workflows, and advanced data processing to enhance sensitivity and reproducibility.

Advanced capabilities include:

- Improved detection of small pigment nanoparticles

- Enhanced differentiation between dispersed particles and aggregates

- Reduced operator variability

- Robust analysis of complex, multi-component ink formulations

As ink technologies evolve toward higher precision, smaller particle sizes, and functional performance requirements, NTA for pigments and inks plays an increasingly important role in supporting accurate ink nanoparticle characterization and reliable pigment aggregation analysis, enabling consistent quality and high-performance applications.

Get Accurate Nanoparticle Analysis for Your Materials

Discover how advanced Nanoparticle Tracking Analysis can support accurate measurement of particle size, concentration and dispersion behavior for your research and industrial applications.