Carbon Nanotubes Analysis

Carbon nanotubes represent a highly advanced class of nanomaterials known for their exceptional mechanical strength, electrical conductivity, thermal stability, and unique one-dimensional structure. These cylindrical carbon structures typically range from a few nanometers in diameter to several micrometers in length and are widely used in electronics, energy storage, composites, sensing, and advanced materials engineering.

Their nanoscale architecture provides extraordinary surface area and electron transport properties, making them ideal for applications requiring high performance and durability. However, the behavior of nanotubes in liquid dispersions and composite systems is strongly influenced by dispersion quality, structural uniformity, and carbon nanotube aggregation.

As industrial and research applications continue to expand, precise carbon nanotube characterization has become increasingly important. Even minor variations in nanotube length distribution, bundle formation, or surface functionalization can significantly affect electrical conductivity, mechanical reinforcement, and processing stability.

NTA for carbon nanotubes has emerged as a powerful analytical approach for understanding dispersion quality and aggregation behavior in liquid systems. By enabling particle-level analysis in suspension, Nanoparticle Tracking Analysis supports improved control over nanotube-based formulations and manufacturing processes.

Fundamentals of Carbon Nanotubes

Carbon nanotubes (CNTs) are cylindrical nanostructures composed of rolled graphene sheets. Their properties depend heavily on structural configuration and synthesis methods.

CNTs are generally classified into:

- Single-Walled Carbon Nanotubes (SWCNTs) – Consist of a single graphene cylinder with diameters typically between 0.7–2 nm.

- Multi-Walled Carbon Nanotubes (MWCNTs) – Contain multiple concentric graphene cylinders with larger diameters.

Common synthesis methods include:

- Chemical vapor deposition (CVD)

- Arc discharge methods

- Laser ablation techniques

- Catalytic growth processes

The resulting nanotube systems exhibit properties strongly influenced by:

- Diameter and length distribution

- Degree of crystallinity

- Surface defects

- Functionalization chemistry

- Inter-tube interactions

These factors directly impact dispersion stability and carbon nanotube aggregation behavior in liquid media.

Types of Carbon Nanotube Dispersions and Systems

Carbon nanotubes are rarely used as dry powders in advanced applications. Instead, they are incorporated into dispersions and composite systems such as:

- Aqueous or solvent-based CNT dispersions

- Polymer nanocomposites

- Conductive inks and coatings

- Energy storage electrode formulations

- Surface-functionalized nanotube suspensions

Across all these systems, effective carbon nanotube characterization is essential to monitor dispersion stability and prevent uncontrolled carbon nanotube aggregation, which can compromise performance.

Importance of Carbon Nanotube Characterization

Carbon nanotubes have a strong natural tendency to form bundles and aggregates due to van der Waals forces and high aspect ratios. Without proper characterization, aggregation can lead to:

- Reduced electrical conductivity

- Poor mechanical reinforcement

- Inconsistent composite properties

- Sedimentation and instability in dispersions

- Batch-to-batch variability

Key drivers for accurate characterization include:

- Ensuring dispersion quality

- Monitoring carbon nanotube aggregation

- Optimizing functionalization strategies

- Supporting formulation development

- Maintaining manufacturing consistency

Traditional ensemble-based methods may not fully capture heterogeneity within nanotube populations, especially in polydisperse or partially aggregated systems.

NTA for Carbon Nanotubes

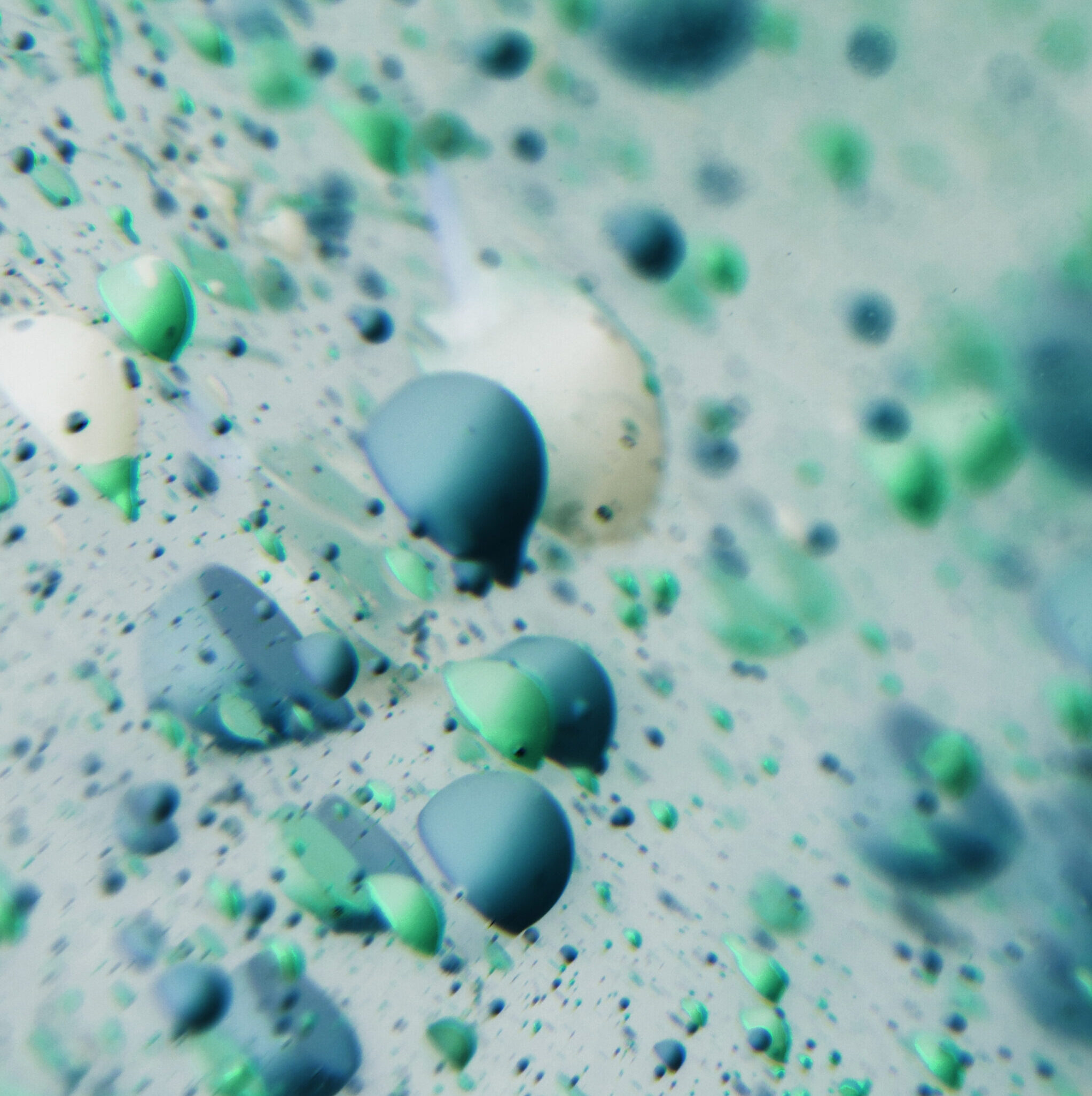

Nanoparticle Tracking Analysis is a single-particle measurement technique that tracks the Brownian motion of individual particles in liquid suspension. When carbon nanotubes or nanotube bundles are illuminated by a laser beam, scattered light from each scattering entity is recorded by a sensitive camera.

By analyzing the trajectories of these particles, diffusion coefficients are calculated, enabling determination of hydrodynamic size and particle concentration.

For dispersions containing nanotubes and nanotube bundles, NTA for carbon nanotubes provides valuable insight into aggregation states and dispersion quality under native liquid conditions.

Advantages of NTA for Carbon Nanotubes

- Particle-resolved measurement: NTA measures individual scattering entities, allowing differentiation between well-dispersed nanotubes and aggregated bundles.

- Number-based size distributions: Number-weighted data reveal the true population of dispersed structures, supporting accurate carbon nanotube characterization.

- Aggregation monitoring: NTA enables detection and quantification of carbon nanotube aggregation in real time during formulation or stability studies.

- Concentration measurement: Absolute particle concentration data assist in process optimization and reproducibility control.

- Liquid-state analysis: Measurements are performed directly in dispersion, avoiding artifacts associated with drying or immobilization.

Carbon Nanotube Measurement Workflow Using NTA

Carbon nanotube characterization using NTA typically follows a structured workflow:

- Controlled dispersion preparation and dilution to an optimal concentration range

- Introduction of the sample into a temperature-controlled measurement chamber

- Laser illumination and optical detection of individual scattering entities

- Tracking of Brownian motion and trajectory analysis

- Extraction of hydrodynamic size distribution and concentration data

This approach supports reproducible analysis across research, development, and industrial environments.

Key Parameters in Carbon Nanotube Characterization

- Hydrodynamic Size: Reflects dispersed nanotubes or bundles in liquid and indicates the presence of carbon nanotube aggregation.

- Size Distribution: Number-based distributions reveal polydispersity and population heterogeneity within dispersions.

- Particle Concentration: Supports formulation control and comparison between batches.

- Aggregation and Stability Behavior: Time-dependent monitoring identifies early-stage carbon nanotube aggregation and sedimentation risks.

Comparison with Other Carbon Nanotube Characterization Techniques

- Dynamic Light Scattering (DLS): Provides rapid ensemble measurements but may be biased toward larger aggregates in polydisperse CNT systems.

- Electron Microscopy: Offers high-resolution structural imaging but requires drying and sample preparation steps that may alter dispersion structure.

- Complementary Role of NTA: NTA for carbon nanotubes bridges the gap by combining particle-level resolution with liquid-state analysis, making it particularly valuable for aggregation monitoring and dispersion optimization.

Role of NTA in Carbon Nanotube Research and Development

- Dispersion optimization: Evaluates surfactant systems and functionalization strategies to reduce carbon nanotube aggregation.

- Composite formulation development: Supports tuning nanotube loading levels for consistent performance.

- Process scale-up monitoring: Ensures uniform dispersion quality during industrial production.

- Stability studies: Long-term tracking of dispersion behavior reveals early aggregation trends.

Quality Control and Manufacturing Applications

In industrial settings, carbon nanotube characterization is essential for ensuring product consistency and performance. NTA supports:

- Batch release testing

- Specification compliance

- Monitoring of carbon nanotube aggregation

- Root cause analysis of dispersion instability

- Continuous process improvement

Direct measurement of dispersion quality enhances confidence in conductive, structural, and energy-related applications.

Advanced NTA Capabilities for Carbon Nanotubes

Modern NTA platforms integrate advanced optics, automated workflows, and improved detection sensitivity to enhance reproducibility and reliability in carbon nanotube characterization.

Advanced capabilities include:

- Improved detection of small dispersed nanotube structures

- Enhanced discrimination between individual nanotubes and bundles

- Reduced operator variability

- Robust analysis of complex, multi-component dispersions

As carbon nanotube applications continue to grow across energy, electronics, and advanced materials sectors, NTA for carbon nanotubes plays an increasingly important role in controlling dispersion quality, minimizing carbon nanotube aggregation, and ensuring reliable material performance.

Get Accurate Nanoparticle Analysis for Your Materials

Discover how advanced Nanoparticle Tracking Analysis can support accurate measurement of particle size, concentration and dispersion behavior for your research and industrial applications.