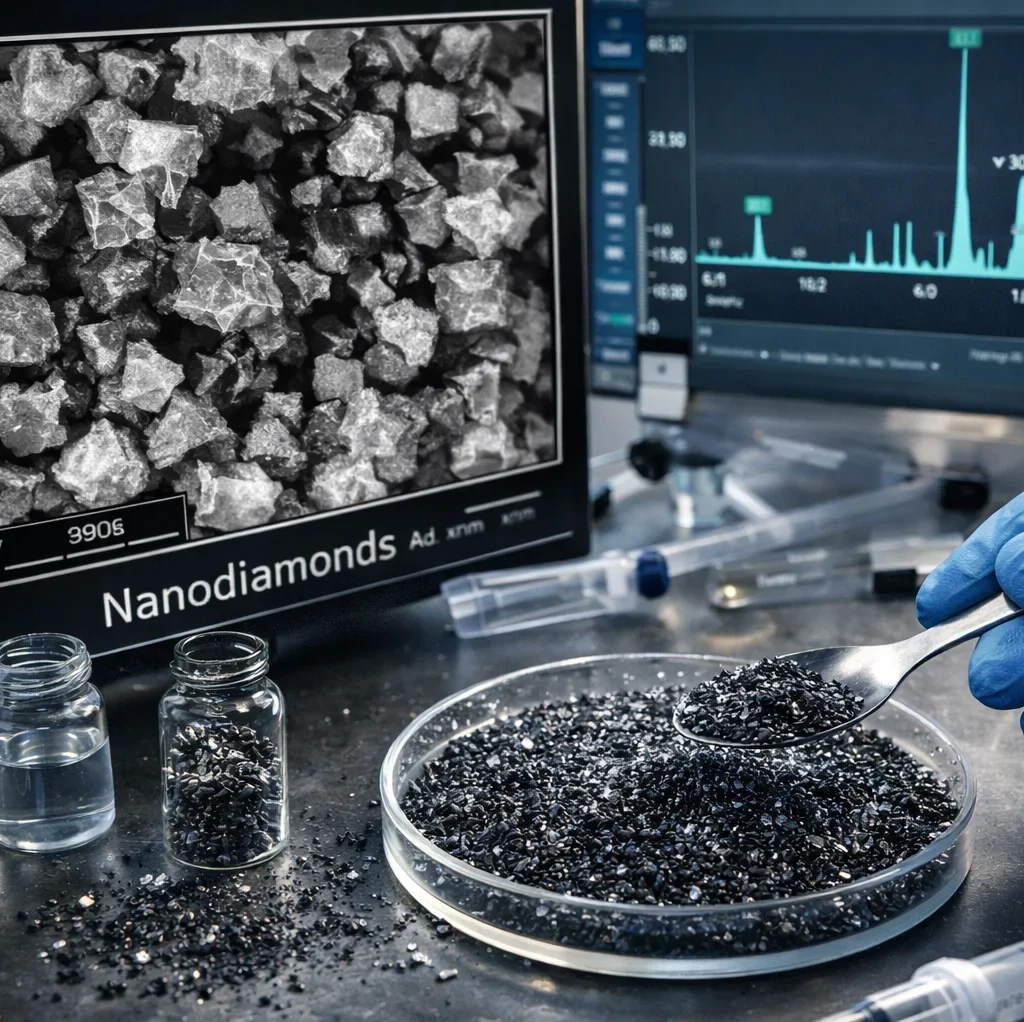

Nanodiamonds Analysis

Nanodiamonds represent a unique class of carbon-based nanomaterials known for their exceptional hardness, chemical stability, biocompatibility, and versatile surface chemistry. These nanoparticles typically range from 2 to 100 nanometers in diameter and are widely used in biomedical research, drug delivery, polishing applications, coatings, quantum sensing, and advanced composites.

At the nanoscale, diamond particles exhibit high surface area, tunable surface functional groups, and stable crystalline structures. However, their performance in practical applications is strongly influenced by dispersion quality, surface chemistry, and particle size distribution. For this reason, precise nanodiamond nanoparticle characterization is essential to ensure reliability and reproducibility.

As applications expand in biotechnology, electronics, and advanced materials engineering, accurate nanodiamond size measurement has become increasingly important. Small variations in size distribution or aggregation state can significantly impact cellular uptake, coating performance, suspension stability, and overall functionality.

NTA for nanodiamonds provides a powerful analytical solution for evaluating particle size, concentration, and aggregation behavior directly in liquid suspension, offering particle-level insight that complements traditional characterization methods.

Fundamentals of Nanodiamonds

Nanodiamonds are nanoscale diamond crystals composed of sp³-bonded carbon atoms arranged in a cubic lattice structure. They are commonly produced through:

- Detonation synthesis

- High-pressure high-temperature (HPHT) methods

- Laser ablation processes

- Chemical vapor deposition (CVD)

Among these, detonation nanodiamonds are widely used due to their small primary particle size and scalable production.

The resulting nanodiamond systems exhibit properties influenced by:

- Primary particle size

- Degree of aggregation

- Surface functional groups (carboxyl, hydroxyl, amine)

- Surface charge and zeta potential

- Purity and residual graphitic carbon content

These characteristics directly affect dispersion stability and performance across industrial and biomedical applications.

Types of Nanodiamond Systems and Dispersions

Nanodiamonds are utilized in various formulations and physical states, including:

- Aqueous nanodiamond dispersions

- Surface-functionalized nanodiamonds

- Polymer nanocomposites

- Biomedical carrier systems

- Polishing and coating suspensions

Across all applications, reliable nanodiamond nanoparticle characterization is necessary to monitor size distribution, concentration, and aggregation behavior.

Importance of Nanodiamond Nanoparticle Characterization

Nanodiamonds possess a strong tendency to form aggregates due to surface interactions and high surface energy. In many applications, uncontrolled aggregation can lead to:

- Reduced bioavailability in drug delivery systems

- Inconsistent polishing performance

- Sedimentation in dispersions

- Variability in composite reinforcement

- Batch-to-batch inconsistency

Key drivers for accurate nanodiamond nanoparticle characterization include:

- Ensuring dispersion stability

- Supporting formulation optimization

- Monitoring processing effects

- Verifying manufacturing consistency

- Enabling regulatory compliance in biomedical applications

Traditional ensemble-based techniques may not fully resolve heterogeneous particle populations, especially when aggregates coexist with primary particles.

NTA for Nanodiamonds

Nanoparticle Tracking Analysis is a single-particle analytical technique that measures particle size and concentration by tracking Brownian motion in liquid suspension. When nanodiamonds are illuminated by a laser beam, scattered light from individual particles is captured by a high-sensitivity camera. By analyzing particle trajectories, diffusion coefficients are calculated, enabling precise nanodiamond size measurement based on hydrodynamic diameter.

NTA for nanodiamonds allows direct visualization and measurement of dispersed nanoparticles and aggregates under native liquid conditions, providing realistic insight into dispersion quality.

Advantages of NTA for Nanodiamonds

- Particle-level analysis: NTA measures individual nanodiamond particles and aggregates rather than generating averaged results.

- Number-based size distributions: Provides realistic representation of nanoparticle populations in polydisperse systems.

- Accurate nanodiamond size measurement: Hydrodynamic diameter reflects real behavior in liquid media, including surface functionalization effects.

- Particle concentration determination: Absolute concentration measurements support dosage control and process reproducibility.

- Aggregation monitoring: Enables detection and quantification of aggregation during formulation and stability studies.

Nanodiamond Measurement Workflow Using NTA

Nanodiamond nanoparticle characterization using NTA typically follows a structured workflow:

- Preparation and controlled dilution of the nanodiamond dispersion

- Introduction into a temperature-controlled measurement chamber

- Laser illumination and visualization of individual particles

- Brownian motion tracking and trajectory analysis

- Data processing to extract size distribution and concentration metrics

This workflow enables reproducible and standardized nanodiamond size measurement across research and industrial environments.

Key Parameters in Nanodiamond Nanoparticle Characterization

- Hydrodynamic Diameter: Represents the effective particle size in liquid, including surface coatings and functional groups.

- Size Distribution: Number-based distributions reveal polydispersity and the presence of aggregates.

- Particle Concentration: Supports formulation consistency and quality control.

- Aggregation and Stability Behavior: Time-dependent monitoring identifies early-stage aggregation and sedimentation risks.

Comparison with Other Nanodiamond Characterization Techniques

- Dynamic Light Scattering (DLS): Provides rapid ensemble measurements but may be biased toward larger aggregates in polydisperse samples.

- Electron Microscopy: Offers high-resolution imaging of primary nanodiamond crystals but requires drying and preparation that may alter dispersion structure.

- Complementary Role of NTA: NTA for nanodiamonds bridges the gap by combining particle-level resolution with liquid-state measurement, making it particularly useful for real-world dispersion analysis.

Role of NTA in Nanodiamond Research and Development

- Formulation optimization: Evaluates dispersants and surface modifications to improve stability.

- Biomedical application development: Supports precise nanodiamond size measurement for controlled cellular interactions.

- Process monitoring: Ensures consistent dispersion quality during production scale-up.

- Stability studies: Long-term monitoring reveals aggregation trends and formulation robustness.

Quality Control and Manufacturing Applications

In industrial environments, nanodiamond nanoparticle characterization is essential for ensuring consistent product performance. NTA supports:

- Batch release testing

- Specification verification

- Monitoring aggregation behavior

- Root cause analysis for variability

- Continuous improvement in manufacturing processes

Direct measurement of size and concentration enhances confidence in biomedical, polishing, coating, and composite applications.

Advanced NTA Capabilities for Nanodiamonds

Modern NTA platforms integrate advanced optics, automated workflows, and improved detection sensitivity to enhance reliability and reproducibility.

Advanced capabilities include:

- Improved detection of smaller nanodiamond particles

- Enhanced differentiation between primary particles and aggregates

- Reduced operator-to-operator variability

- Robust analysis of complex, multi-component dispersions

As nanodiamond technologies continue to evolve across biomedical, industrial, and advanced materials sectors, NTA for nanodiamonds plays a critical role in enabling precise nanodiamond nanoparticle characterization and accurate nanodiamond size measurement, supporting innovation and high-performance material development.

Get Accurate Nanoparticle Analysis for Your Materials

Discover how advanced Nanoparticle Tracking Analysis can support accurate measurement of particle size, concentration and dispersion behavior for your research and industrial applications.