Latex Nanoparticles Analysis

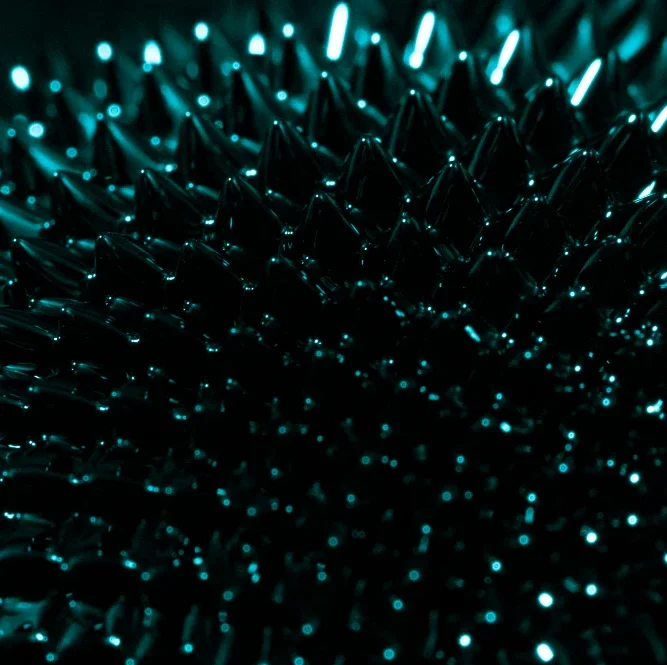

Latex nanoparticles represent one of the most widely studied and industrially relevant classes of polymer-based nanomaterials. Produced as stable colloidal dispersions, these particles typically consist of synthetic polymers such as polystyrene, polymethyl methacrylate (PMMA), or copolymer systems engineered to deliver controlled size, surface chemistry, and mechanical properties. Their predictable behavior, scalability, and chemical versatility make latex nanoparticles indispensable across materials science, industrial R&D, coatings, diagnostics, and analytical method development.

As applications increasingly rely on nanoscale precision, accurate characterization of latex nanoparticles has become essential. Particle size, size distribution, and concentration directly influence dispersion stability, optical performance, film formation, rheology, and end-use reliability. Even small deviations in these parameters can lead to measurable changes in material behavior, making robust analytical techniques a foundational requirement for both research and manufacturing environments.

Nanoparticle Tracking Analysis (NTA) has become a critical tool for latex nanoparticle measurement, offering single-particle resolution and number-based analysis in liquid suspension. By directly observing particle motion, NTA provides insights into latex nanoparticle populations that are not accessible through ensemble-averaging techniques alone.

Composition and Properties of Latex Nanoparticles

Latex nanoparticles are typically synthesized through emulsion polymerization or related processes that yield spherical polymer particles dispersed in an aqueous medium. The resulting particles can be engineered with precise control over:

- Particle diameter

- Surface charge

- Functional groups

- Mechanical stiffness

- Colloidal stability

Common polymer systems include:

- Polystyrene latex nanoparticles

- PMMA latex nanoparticles

- Styrene-butadiene copolymers

- Functionalized polymer beads

These materials are frequently stabilized using surfactants or surface modifications to prevent aggregation and ensure long-term dispersion stability. Their optical contrast, chemical robustness, and tunable surface chemistry make latex nanoparticles well suited for advanced nanoparticle characterization techniques, including NTA.

Industrial and Research Applications of Latex Nanoparticles

- Materials Science and Colloidal Research: Latex nanoparticles are widely used as model colloidal systems for investigating particle–particle interactions, aggregation kinetics, and suspension stability. Their uniformity and reproducibility enable controlled studies of fundamental colloidal behavior under varying chemical and physical conditions.

- Coatings, Paints, and Surface Technologies: In coatings and surface formulations, latex nanoparticles play a critical role in determining film formation, adhesion, mechanical durability, and optical properties. Particle size distribution influences packing efficiency and surface smoothness, making accurate measurement essential during formulation optimization and quality control.

- Diagnostic and Analytical Reagents: Functionalized latex nanoparticles are commonly used in diagnostic assays, including immunoassays and lateral flow tests. In these applications, particle size and concentration directly impact signal strength, sensitivity, and reproducibility.

- Calibration and Reference Standards: Latex nanoparticles are frequently employed as reference materials for validating nanoparticle measurement instruments and analytical workflows. Their stable and well-characterized properties make them suitable for benchmarking performance across multiple techniques.

- Industrial Manufacturing and Quality Assurance: Manufacturers rely on precise latex nanoparticle measurement to ensure batch consistency, monitor process stability, and meet internal and regulatory specifications. Routine characterization supports early detection of aggregation, contamination, or formulation drift.

Importance of Accurate Latex Nanoparticle Measurement

Latex nanoparticle dispersions may appear uniform, yet small subpopulations of aggregates or oversized particles can significantly influence performance. Key analytical challenges include:

- Detection of minor particle populations

- Differentiation between primary particles and aggregates

- Measurement at low or variable concentrations

- Analysis in complex formulations containing additives or surfactants

Addressing these challenges requires analytical techniques capable of resolving individual particles rather than relying solely on bulk averages.

Advantages of NTA for Latex Nanoparticles

- Single-Particle Resolution: Unlike ensemble techniques, NTA measures each latex nanoparticle independently. This enables detection of subtle heterogeneity and minor populations that may be masked in averaged measurements.

- Number-Based Size Distributions: Latex nanoparticle measurement using NTA produces number-weighted size distributions, providing a realistic representation of particle populations and improving interpretation for formulation and QC workflows.

- Particle Concentration Measurement: NTA directly measures particle concentration in particles per milliliter, a critical parameter for diagnostics, formulation reproducibility, and manufacturing control.

- Native-State Analysis: Measurements are performed in liquid suspension, preserving the physical state of latex nanoparticles and minimizing artifacts associated with drying or immobilization.

Advantages of NTA for Ceramic Nanoparticles

- Particle-resolved measurement: NTA measures individual ceramic nanoparticles rather than averaged populations, enabling detection of minor particle fractions, aggregates, and secondary size modes.

- Number-based size distributions: NTA produces number-weighted distributions that provide a realistic representation of particle populations in polydisperse systems.

- Particle concentration determination: Absolute particle concentration measurements support process control, quality assurance, and comparative studies across synthesis batches or formulation conditions.

- Native liquid-state analysis: Measurements are performed directly in dispersion, preserving the physical state of ceramic nanoparticles and minimizing artifacts associated with drying or immobilization.

Latex Nanoparticle Measurement Workflow Using NTA

Ceramic nanoparticle characterization using NTA typically follows a structured workflow:

- Controlled dilution of the ceramic nanoparticle dispersion to an optimal particle concentration

- Introduction of the sample into a temperature-controlled measurement chamber

- Optical detection and tracking of individual ceramic nanoparticles

- Data processing to extract particle size, size distribution, and concentration metrics

This workflow supports reproducible analysis across a wide range of ceramic nanoparticle systems.

Measurement Parameters Relevant to Latex Nanoparticles

- Particle Size: NTA measures hydrodynamic diameter, reflecting how latex nanoparticles move within a liquid environment, including the effects of surface coatings and stabilizers.

- Size Distribution: Number-based size distributions enable identification of aggregation, secondary populations, and distribution broadening over time.

- Particle Concentration: Accurate concentration measurement supports:

- Batch comparison

- Stability studies

- Assay development

- Process monitoring

- Aggregation and Stability Assessment: Changes in particle size and concentration over time provide insight into dispersion stability, flocculation, or formulation degradation.

Comparison with Other Latex Nanoparticle Measurement Techniques

- Dynamic Light Scattering (DLS): DLS provides ensemble-averaged size information but is highly sensitive to larger particles and aggregates. Polydisperse latex nanoparticle samples can lead to biased results.

- Electron Microscopy: Electron microscopy delivers high spatial resolution but requires extensive sample preparation and does not represent particles in their native liquid state.

- NTA Complementarity: NTA for latex nanoparticles complements these techniques by offering direct, liquid-phase, single-particle measurements with both size and concentration information.

Role of NTA in Latex Nanoparticle Development

- Formulation Optimization: NTA supports optimization of polymerization conditions, surfactant selection, and stabilization strategies by providing rapid feedback on particle size and dispersion quality.

- Scale-Up and Manufacturing: During scale-up, NTA enables monitoring of size consistency and concentration control, helping ensure that laboratory-scale performance translates into production environments.

- Quality Control and Batch Release: Routine latex nanoparticle measurement using NTA ensures compliance with internal specifications and supports early detection of deviations that could impact product performance.

Advanced NTA Capabilities for Polymer and Latex Systems

Modern NTA platforms integrate enhanced optics, improved sensitivity, and automated workflows that improve reproducibility and data confidence. These capabilities are particularly valuable for latex nanoparticles, where small changes in size or concentration can be meaningful.

Advanced systems support:

- Improved detection of smaller latex nanoparticles

- Greater measurement repeatability

- Reduced operator-dependent variability

- Reliable analysis of complex or mixed dispersions

Latex Nanoparticles as Analytical Benchmarks

Latex nanoparticles are commonly used as benchmark materials for validating nanoparticle characterization methods. NTA plays a central role in establishing measurement confidence by providing traceable, particle-level data that can be compared across instruments and laboratories.

This benchmarking function is essential for:

- Method development

- Instrument qualification

- Inter-laboratory studies

Expanding Material Analysis Beyond Biological Systems

The ability to characterize latex nanoparticles highlights the broader applicability of NTA across non-biological materials. Polymer colloids, composite nanoparticles, and engineered dispersions benefit from the same single-particle measurement principles, reinforcing NTA as a versatile platform for material analysis.

By supporting both research-driven and industrial workflows, NTA enables consistent characterization across diverse material classes without requiring fundamentally different analytical approaches.

Get Accurate Nanoparticle Analysis for Your Materials

Discover how advanced Nanoparticle Tracking Analysis can support accurate measurement of particle size, concentration and dispersion behavior for your research and industrial applications.